Constance Ißbrücker, Head of Environmental Affairs, EUBP

The consequences of climate change and the finite nature of fossil resources constitute two broadly acknowledged challenges for society in the decades to come. Bioplastics, which are derived fully or at least in part from renewable resources, have the unique advantage over conventional plastics to reduce the dependency on non-renewable feedstock such as crude oil and to reduce greenhouse gas emissions. Yet, the use of biomass to produce bio-based plastics raises questions about a potential competition with food and feed. But how much land do we really need to produce bio-based plastics today and in the mid-term?

Constance Ißbrücker, Head of Environmental Affairs at European Bioplastics, gives some insights in this debate.

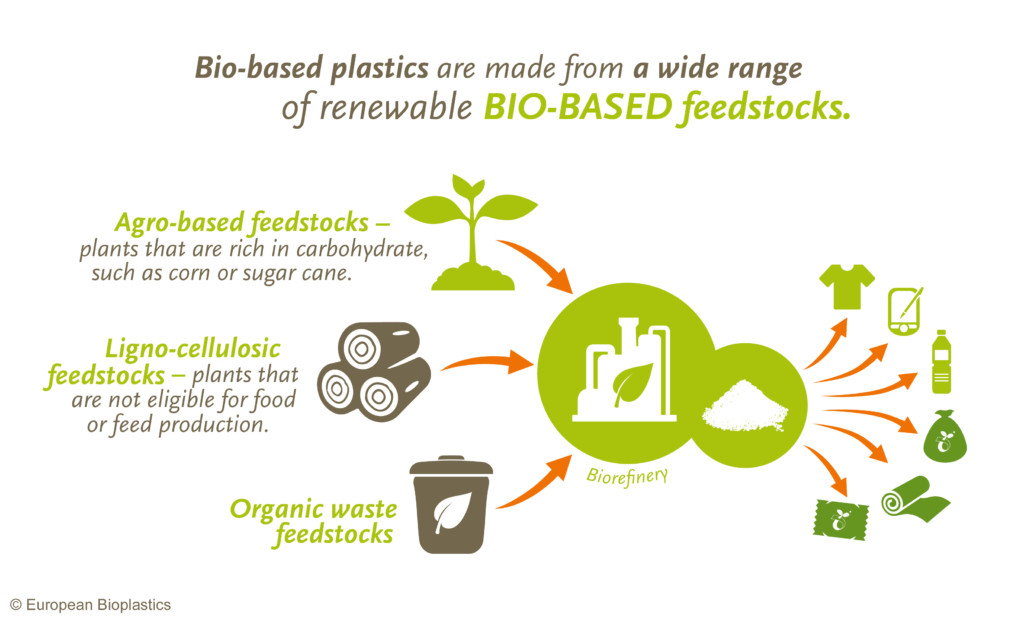

Today, bioplastics are predominantly produced from agro-based feedstock, i.e. plants that are rich in carbohydrates, such as corn or sugarcane. At the same time, the bioplastics industry is investing in the research and development to diversify the availability of biogenic feedstock for the production of bio-based plastics. The industry particularly aims to further develop fermentation technologies that enable the utilisation of ligno-cellulosic feedstock sources, for example non-food crops but also agricultural waste materials.

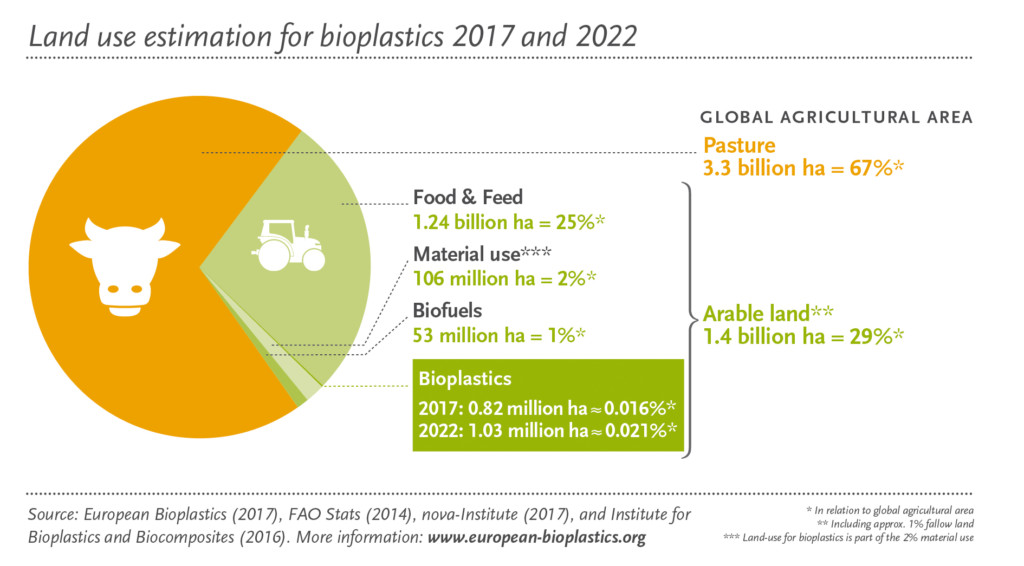

According to the estimation published by European Bioplastics at the end of last year[1], the land area used to grow biomass for the production of bioplastics in 2017 corresponded to 0.016 percent of the global agricultural area, 97 percent of which are used to grow food and feed. Even with the predicted high growth-rates of the bioplastics industry over the next years, the land-use share would only slightly increase to up to 0.021 percent of the agricultural area by 2022.

This clearly shows, that there is not competition between the use of biomass to produce bioplastics and the use of biomass for food and feed. At the same time, there are various ways to ensure a sufficient supply of biomass for the production for food, feed, and material uses (including bioplastics) now and in future. These include:

- Broadening the base of feedstock: The bioplastics industry is currently working mostly with agro-based feedstock. Several projects, however, are already looking into using plant residues or other ligno-cellulosic feedstock.

- Increasing yields: Improving the efficiency of industrial conversion of raw materials into feedstock, for example by using advanced or specifically tailored microorganisms and optimised physical and chemical processes that would increase the total availability of resources.

- Taking fallow land into production: There is still plenty of arable land in various geographical regions available for agricultural production, even in the European Union.[2]

Responsibly sourced and monitored agricultural crops are still the main feedstock option for bioplastics, since they are more land-efficient than non-food crops due to highly efficient processes. What is more, the use of by-products of these food crops, which is often ligno-cellulosic feedstock would further increase resource efficiency. There is evidence that the industrial and material use of biomass may in fact serve as a stabilizer for food prices, providing farmers with more secure markets and thereby leading to more sustainable production. Independent third party certification schemes for sustainable sourcing and responsible agricultural practices (i.e. by RSB or ISCC) do already exist and can help to take social, environmental and economic criteria into account and to ensure that bioplastics are a purely beneficial innovation.

Calculation method:

The data on the land area needed to produce bioplastics are estimations based on production capacities, which can be higher than the volumes actually produced, polymer-specific process routes, and an allocation factor. Additionally, several other assumptions were made, for example about the kind of feedstock used (different feedstocks used for the same polymer by different manufacturers based on availability and location), about the share of the processed plant actually used for the polymer production (other parts of the same plant might be used for other purposes), or about the actual bio-based content of the final resin. The data is partly based on specific information provided by bioplastic producers that offer own calculations on the average land use for their biopolymer resin or products, based on specific agricultural practices, climatic conditions, or crop variety used. In cases where no company data was available, the estimations are based on general process routes for the production of bioplastics published by IfBB Hanover[3]. These process routes provide data on the area of land used to produce one tonne of a specific biopolymer, yet, they are calculated under the assumption that the whole crop is used for the production of the bioplastic resin, which is not always the case. In order to correct this assumption, EUBP uses an allocation factor developed by nova-Institute[4], which distinguishes between the percentage of certain crops that is used in industrial production (including bioplastics) and the share used for other purposes, such as food and feed.

[1] European Bioplastics in collaboration with nova-Institute (2017): Global bioplastics market data (report).

[2] Various figures from different sources exist about unused arable land, including data by the French National Institute For Agricultural Research of 2.6 billion hectares of untapped potential (article in ParisTech, 2011); the nova-Institute calculates 570 million hectares based on figures of OECD and FAO (2009). The bottom line – there is an ample amount of unused land available.

[3] Institute for Bioplastics and Biocomposites, Biopolymers – Facts and statistics, 2016

[4] Carus et. al (nova institute), “Food or non food: Which agricultural feedstocks are best for industrial uses?”, 2013/07