“Plastics play an essential role in modern society. However, their value chain is currently unsustainable, contributing to the generation of climate changing emissions and increasing waste and pollution. Reducing such impacts while retaining plastics’ usefulness requires a shift towards a more circular and sustainable plastics system”, states the European Environment Agency (EEA) in a recently published briefing paper.

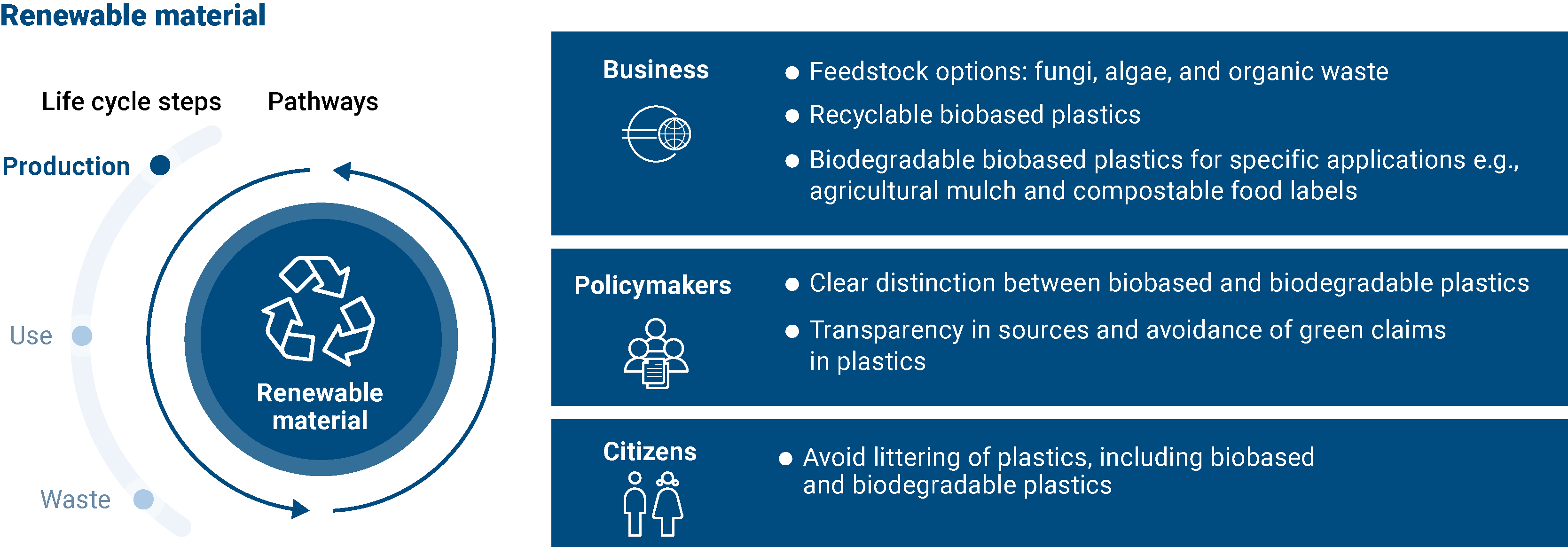

The paper points out three different pathways that can lead to a more circular, sustainable plastics system. One of them focusses on renewable materials, including biobased plastics, while the other two pathways focus on smarter use and increased circularity. The EEA authors identified good practice examples from across Europe for each of these pathways and which are to serve as an inspiration for how to make plastics more sustainable and circular.

Source: Developed by the EEA and the European Topic Centre on Circular Economy and Resource Use (ETC/CE) — illustration by the Collaborating Centre on Sustainable Consumption and Production (CSCP) and the EEA.

The renewable material pathway for plastics, in particular, seeks to promote renewable feedstock-based solutions. It focuses on the beginning of the value chain, on feedstock choices, and on feedstock supply. In this regard, EEA explicitly mentions the use of biobased plastics, which help to reduce the dependency on fossil-based feedstocks. Additional possible benefits of using renewable feedstocks, according to EEA, include the reduction of greenhouse gas emissions and, if the feedstocks are locally and sustainably sourced, the increase in rural development and reduction of the dependence on imported feedstock.

The EEA paper especially emphasizes the potential of biobased plastics to reduce CO2 emissions if they are produced responsibly and recycled rather than incinerated. With regards to the different feedstocks for biobased plastics, EEA advocates for second and third generation feedstock. They are not suitable for food and feed and include non-food crops such as algae or by-products of food and feed production, such as corn stover and waste streams, e.g., biowaste. Although second and third generation feedstock is increasingly being researched and used for industrial purposes, it is important to note that most bioplastics today are still being produced from first generation feedstock. First generation feedstock derives from carbohydrate-rich plants, such as corn or sugar cane, and is still the most efficient feedstock, as these crops require the least amount of land to grow and produce the highest yields. The available data shows that the land used to grow the renewable feedstock needed to produce bioplastics in 2022 accounted for around 0.015 percent of the global agricultural area. Even with the predicted increase of global bioplastics production until 2027, the land use share is expected to increase to only around 0.06 percent. In relation to the available agricultural area, this share is minimal. Thus, EUBP argues, there is no competition between the renewable feedstock for food and feed and the production of bioplastics.

In comparison with the other two pathways, the renewable material pathway, according to the EEA authors, is the least developed in terms of commercial availability. However, many of the identified good practice examples clearly show the high potential for further development. This finding goes in line with the “EU Bioeconomy Strategy Progress Report” published by the European Commission in June 2022. The report, too, acknowledged the important role of the biobased industry, including bioplastics, in addressing environmental challenges and providing viable alternatives to conventional, fossil-based products. However, it also identified areas which still needed to improve, especially the regulatory environment to further promote the mobilisation of private and public investment. It also emphasized the necessity to ensure that successful research results in the biobased field receive market access.

Hence, the European Union should adapt the regulatory environment for biobased materials accordingly. There are several legislative processes which are currently underway and are a crucial opportunity to promote these innovative and sustainable materials, especially the current revision of the Packaging and Packaging Waste Regulation and the revision of the Bioeconomy Strategy.