Biodegradables and material recycling – a paradox?

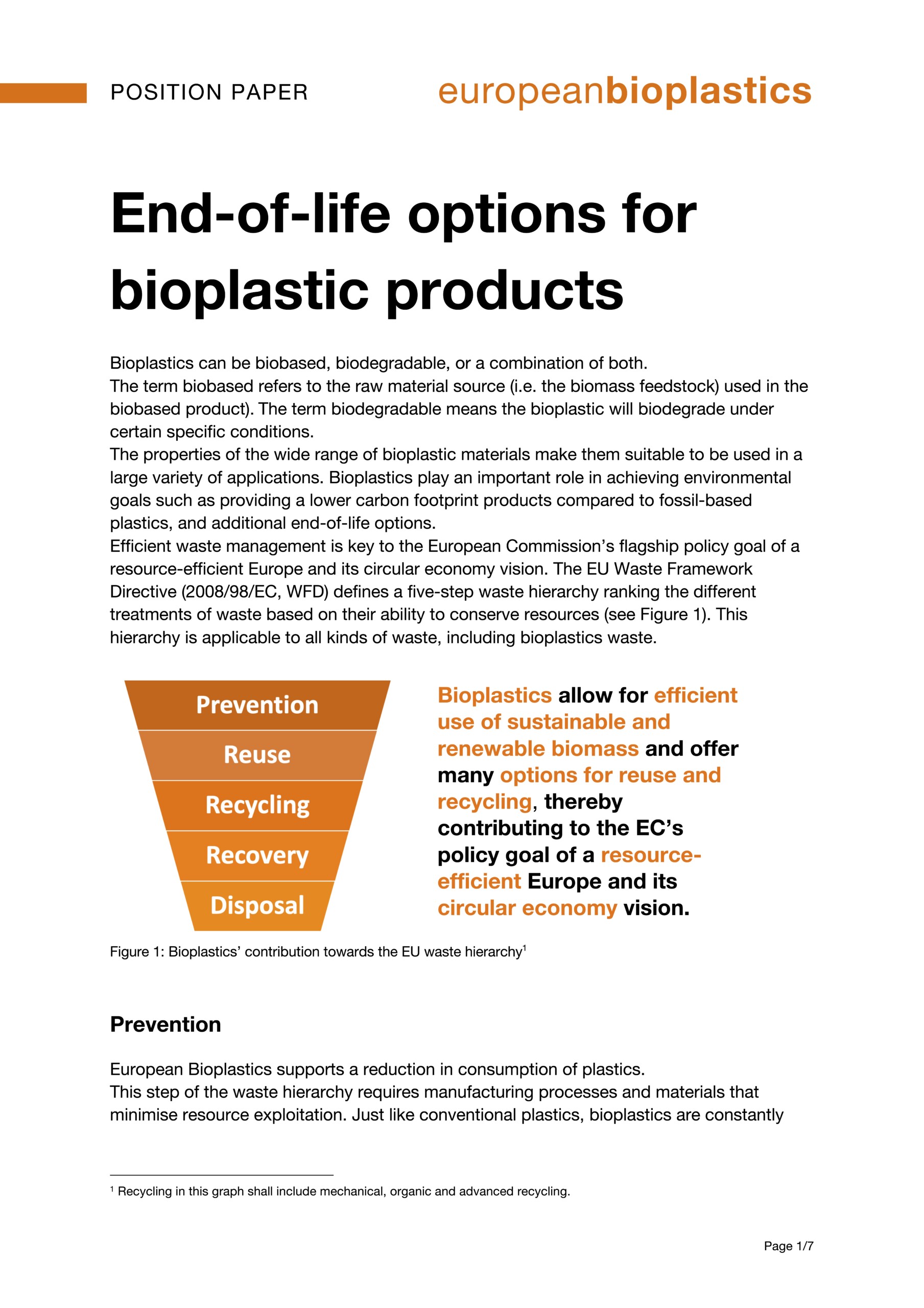

Open the document Biodegradables are sortable and suitable for material recycling streams. Efficient sorting of all plastics is essential for high quality recycling outputs. Biodegradable plastics have the potential to play a significant role in advancing a circular economy by addressing several environmental challenges. They can help mitigate plastic waste, promote sustainable resource utiliszation, [...]